The process of making a t-shirt from start to finish involves several stages, from cotton farming to the final product. Here’s a detailed breakdown:

1. Cotton Cultivation and Harvesting

- Cultivation: Cotton plants are grown in fields. These plants require a warm climate, adequate water, and proper soil conditions to thrive.

- Harvesting: Once the cotton bolls (seed pods) are mature, they are harvested, usually with the help of machines like cotton pickers.

2. Ginning

- Separation: The harvested cotton is taken to a gin where the fibers are separated from the seeds. The fibers, called lint, are then compressed into bales for easier transportation.

3. Spinning

- Carding: The cotton lint is cleaned and aligned into strands called slivers.

- Spinning: The slivers are spun into yarn through a series of processes, including drawing, roving, and spinning. This yarn can be of various thicknesses depending on the desired fabric texture.

4. Knitting

- Fabric Production: The yarn is knitted into fabric using circular knitting machines or flat knitting machines. T-shirt fabric is typically made using a jersey knit, which is soft and stretchy.

5. Dyeing and Finishing

- Dyeing: The knitted fabric is dyed to the desired color in large dyeing machines. This can be done either in the yarn stage (yarn dyeing) or after the fabric is knitted (piece dyeing).

- Finishing: The dyed fabric is treated with various chemicals to enhance properties like softness, durability, and shrink resistance. It is then dried and set to maintain its shape.

6. Cutting

- Pattern Making: Patterns for different t-shirt sizes and styles are created.

- Cutting: The fabric is laid out in layers and cut into the shapes of the various parts of the t-shirt (front, back, sleeves) using cutting machines or laser cutters.

7. Sewing

- Assembly: The cut fabric pieces are sewn together by skilled workers using industrial sewing machines. This involves attaching the front and back panels, sewing the shoulder and side seams, attaching sleeves, and hemming the neckline and bottom edges.

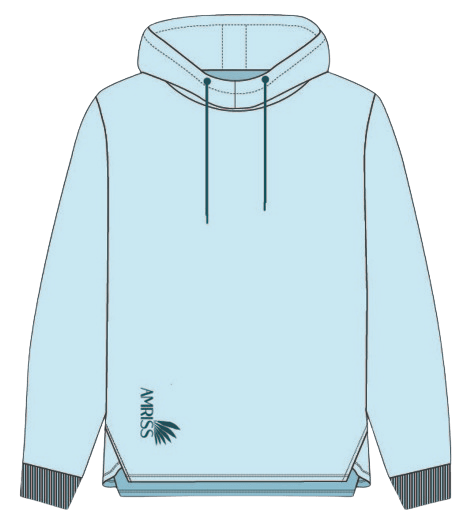

8. Printing and Embellishment

- Screen Printing: Designs or logos are applied to the t-shirt using screen printing, heat transfer, or direct-to-garment printing techniques.

- Embroidery: Sometimes, designs are embroidered onto the t-shirt for a textured and durable finish.

9. Quality Control

- Inspection: Each t-shirt undergoes a quality check to ensure it meets the required standards in terms of stitching, sizing, and design application.

- Correction: Any defects are corrected or the t-shirt is discarded if it does not meet the standards.

10. Packaging

- Tagging: Brand tags and care labels are attached.

- Folding and Packaging: The t-shirts are folded neatly, sometimes wrapped in plastic, and packed into boxes for shipping.

11. Distribution

- Shipping: The packaged t-shirts are shipped to retailers, wholesalers, or directly to consumers via various distribution channels.

12. Retail

- Display and Sale: Finally, the t-shirts reach retail stores or online platforms where they are made available for purchase by customers.

Each step in this process involves specific technologies, machinery, and skilled labor, contributing to the final product’s quality and appearance.